What are 51.2V 200Ah Batteries?

A 51.2V 200Ah rack battery is a high-capacity energy storage device commonly used in applications requiring substantial and reliable power. The “51.2V” refers to its nominal voltage, while “200Ah” indicates its capacity, meaning it can supply 280 amperes of current for one hour.

How are 51.2V 200Ah Rack Batteries manufactured?

Such batteries are typically manufactured using lithium iron phosphate (LiFePO4) cells. These cells are assembled into modules, and then multiple modules are connected in series and parallel to achieve the desired voltage and capacity. The entire assembly is housed in a sturdy rack for easy installation and management.

The manufacturing process for 51.2V 200Ah rack batteries, typically used in large-scale energy storage systems, involves several key steps:

1. Cell Manufacturing:

- Individual Cells: Each cell within the rack is manufactured using similar processes as smaller lithium-ion batteries. This typically involves preparing cathode and anode materials, assembling them with a separator, and filling the cell with electrolyte.

- Cell Testing: Each cell undergoes rigorous testing to ensure its performance, capacity, and safety.

2. Battery Module Assembly:

- Grouping: Multiple cells are grouped together into modules. The number of cells per module depends on the desired voltage and capacity of the final battery.

- Interconnection: The cells within a module are connected in series to increase the voltage and in parallel to increase the capacity.

- Module Testing: The module is tested to verify its performance and ensure proper cell balancing.

3. Rack Assembly:

- Module Integration: Multiple modules are integrated into a rack structure. The rack design provides mechanical support, cooling, and electrical connectivity for the modules.

- Rack Management System (BMS): A sophisticated BMS is installed to monitor and control the battery rack’s operation, including cell balancing, temperature management, and safety features.

- Rack Testing: The assembled rack undergoes comprehensive testing to ensure its overall performance, safety, and compliance with relevant standards.

Key considerations in rack battery manufacturing:

- Scalability: Rack batteries are designed to be scalable, allowing for the construction of large-scale energy storage systems by combining multiple racks.

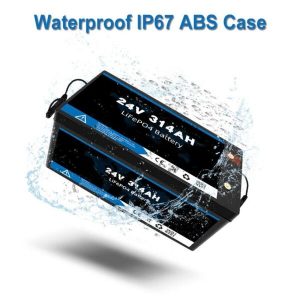

- Safety: Safety is a paramount concern in rack battery manufacturing. Robust safety features, including fire suppression systems and overcharge/overdischarge protection, are incorporated into the design.

- Thermal Management: Effective thermal management is crucial to prevent overheating and ensure optimal battery performance. Cooling systems, such as fans or liquid cooling, are integrated into the rack design.

- Cell Consistency: Ensuring consistent performance among the individual cells within a rack is essential for optimal energy storage and long-term reliability.

- BMS Complexity: The BMS for a rack battery system is complex, requiring advanced algorithms and hardware to manage the large number of cells and modules.

The manufacturing process for 51.2V 200Ah rack batteries is a complex and precise undertaking that requires careful attention to detail and adherence to stringent quality standards. These batteries play a vital role in supporting renewable energy integration and grid stability.

Where are 51.2V 200Ah Rack Batteries used?

Due to their high energy density and long cycle life, 51.2V 200Ah rack batteries find applications in:

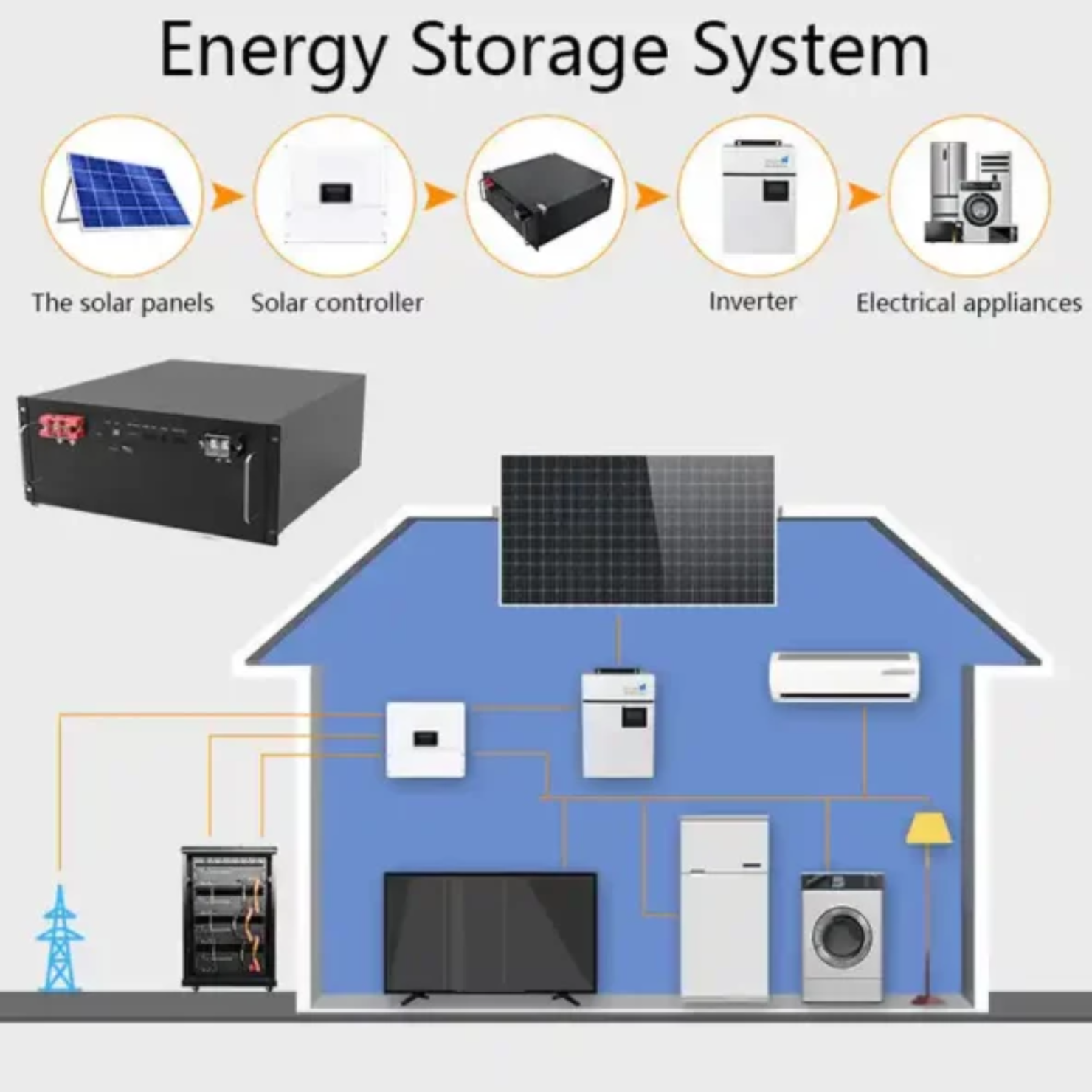

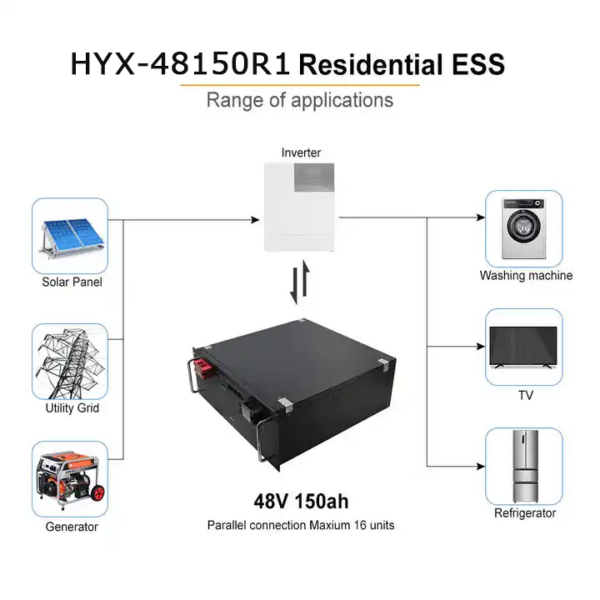

- Renewable energy systems: They are often paired with solar panels or wind turbines to store excess energy for later use.

- Electric vehicles: These batteries power electric buses, trucks, and other heavy-duty vehicles.

- Uninterruptible power supplies (UPS): They provide backup power for critical systems like data centers and hospitals.

- Off-grid power systems: They are ideal for remote locations where grid power is unavailable.

Why are 51.2v 200ah Rack Batteries Popular?

- High energy density: They pack a lot of energy into a relatively small space.

- Long cycle life: LiFePO4 chemistry offers excellent cycle life, meaning they can be charged and discharged many times without significant capacity loss.

- Safety: LiFePO4 batteries are generally safer than other lithium-ion battery chemistries, with a lower risk of thermal runaway.

- Scalability: They can be easily scaled to meet various power requirements by connecting multiple modules.

In essence, a 51.2V 200Ah rack battery is a versatile power source that offers high performance, long life, and safety. Its applications span across various industries, making it a popular choice for energy storage solutions.

The 48V 200Ah LiFePO4 home energy storage battery holds a prominent position in the market due to its exceptional features and benefits. As the demand for residential energy storage solutions continues to rise, this battery offers homeowners a reliable and efficient way to store and utilize renewable energy.

By investing in these batteries, homeowners can enjoy several advantages. Firstly, they gain greater control over their energy usage and reduce their dependence on the grid. Excess energy generated from solar panels or other renewable sources can be stored in the LiFePO4 battery and used during peak demand or when the grid is down, ensuring a consistent power supply. This not only increases energy independence but also reduces reliance on fossil fuel-based electricity, leading to lower utility bills and a smaller carbon footprint.

Moreover, the LiFePO4 chemistry provides enhanced safety features, making it a reliable choice for home energy storage. The battery’s long cycle life ensures durability and cost-effectiveness, as it can withstand frequent charge-discharge cycles without significant degradation. Homeowners can have peace of mind knowing that their energy storage system is built to last.

Looking ahead, the future of energy storage is promising. As renewable energy installations and electric vehicle adoption continue to grow, the demand for energy storage solutions will increase. Homeowners will seek more advanced and efficient batteries to optimize their energy usage and maximize self-consumption.

In this context, the ThinkedPow factory plays a crucial role. They excel in the production of high-quality LiFePO4 batteries, leveraging advanced manufacturing facilities and expertise. Their commitment to quality control and rigorous testing procedures ensures that customers receive reliable and safe batteries that meet industry standards.

Furthermore, ThinkedPow’s dedication to innovation positions them at the forefront of battery technology advancements. They invest in research and development to improve battery performance, increase efficiency, and enhance safety features. This commitment to continuous improvement ensures that customers have access to cutting-edge energy storage solutions that meet their evolving needs.

In summary, the 48V 200Ah LiFePO4 home energy storage battery holds a significant position in the market, offering homeowners greater energy independence, reduced utility bills, and peace of mind. The future of energy storage is promising, with a growing demand for advanced residential energy storage solutions. The ThinkedPow factory’s expertise, advanced manufacturing facilities, and commitment to innovation make them a reliable and trustworthy choice for high-quality batteries. By choosing these batteries, homeowners can embrace a sustainable future while enjoying the benefits of efficient and reliable home energy storage.

48V 200Ah LiFePO4 Battery Specification Datasheet

| Item | General Parameters |

| Rated Capacity | (Typ.) 200Ah |

| (Min.) 200Ah | |

| Nominal Voltage | 48V |

| End of Charge Voltage | 39V±0.5V |

| Battery limit voltage | 54.75V±0.5V |

| Internal Impedance | ≤100mΩ |

| Charging cut- off current | 0.02C |

| Charging time | 3-5h |

| Over- Charge Voltage Protection (cell) | 3.65V |

| Max continuous charge current | 100A |

| Maximum Continuous Discharging Current | 100A |

| Over- discharge Voltage Protection (cell) | 2.70V |

| Short circuit protection | Yes, with BMS Protection |

| Operation Temperature Range | Charge :0~45℃ |

| Discharge :- 10~60℃ | |

| Storage Temperature Range | 1 month : -20℃ ~ 45℃ |

| 3 months: -20℃ ~ 45℃ | |

| 1 year : -20℃ ~ 25℃ | |

| Applications | Electric Vehicles (EVs); Energy Storage Systems (ESS); Portable Electronics; Backup Power Solutions; Renewable Energy Integration; Off-Grid Power Systems; Marine and RV Applications; Industrial and Commercial Applications |

BMS Protection System

– Over-charge protection

– Over-discharge protection

– Over-current protection

– Short circuit protection

– Temperature detection protection

– Balance function

– Bluetooth function

Reviews

There are no reviews yet.