一篇关于24V 280Ah磷酸铁锂电池的深度文章,内容涵盖其制造工艺、市场趋势和应用:

了解 24V 280Ah 磷酸铁锂电池

这款24V 280Ah磷酸铁锂电池是一款高容量、深循环可充电电池组,采用磷酸铁锂(LiFePO4)化学材料制成。这种配置的电池组是一种强大的储能解决方案,由于其性能优于传统的铅酸电池,因此在各个行业中越来越受欢迎。

主要规格:

- 电压(24V):电池组的标称电压为24伏。这是通过将多个磷酸铁锂电池(通常标称电压为3.2V)串联起来实现的。在这种情况下,通常串联八个电池(8*3.2V=25.6V,通常四舍五入为24V)。

- 容量(280Ah):电池可提供 280 安时 (Ah) 的电流。这意味着理论上,它可以提供 280 安培的电流持续 1 小时,或提供 28 安培的电流持续 10 小时,或提供 1 安培的电流持续 280 小时,之后才需要充电。

- 能量(6.72 kWh):储存的总能量近似计算为电压 * 容量(24V*280ah=6.72kWh,或 6.72kWh)。

为什么选择磷酸铁锂?

磷酸铁锂是锂离子电池化学的一个分支,具有显著的优势:

1. 安全性:磷酸铁锂(LiFePO4)以其优异的热稳定性和化学稳定性而闻名,使其本质上比其他锂离子电池(如NCA或NCM)更安全。它们具有很强的抗热失控能力。

2. 循环寿命长:这些电池可以承受数千次的充放电循环(通常为 3,000 至 8,000 次以上),这意味着更长的使用寿命和更好的长期投资回报。

3. 轻便:它们比同等容量的铅酸电池轻得多。

4. 性能:它们提供高充电和放电率(高 C 倍率),可实现快速充电和高功率爆发输出。

24V 280Ah磷酸铁锂电池是如何制造的?

24V 280Ah LiFePO4 电池组的制造过程是一个多阶段过程,它将电芯生产与电池组组装结合在一起。

1.磷酸铁锂电池制造:

该过程首先是生产单个 3.2V 电池(通常采用棱柱形或软包形式):

- 电极制备:将活性材料(正极为磷酸铁锂,负极为石墨)、导电添加剂和粘结剂混合成浆料。将这些浆料涂覆到铝箔(正极)和铜箔(负极)集流体上。

- 干燥和切割:将涂覆电极干燥、压延(压制成特定厚度),然后切割成精确尺寸。

- 电池组装:在阴极和阳极之间放置隔膜(一种防止短路的聚合物薄膜)。这些层堆叠或缠绕在一起,并密封在电池外壳内(例如,棱柱形电池的铝制外壳)。

- 电解液填充:将非水系电解液注入电池外壳。

- 密封和成型:电池密封后,初始充放电循环(称为“成型”过程)会激活电极材料并形成稳定的固体电解质界面(SEI)层,这对于电池的性能和寿命至关重要。

- 分级和分拣:对电芯进行容量、内阻和电压测试,然后进行分级和分拣,以确保最终电池组中只使用匹配的高质量电芯。

2. 电池组组件(24V 280Ah 电池组):

这里将各个电芯集成到最终的 24V 280Ah 配置中:

- 串并联连接:为了达到 24V(标称)和 280Ah 的额定值,需要将八节 3.2V、280Ah 容量的电芯串联(8S)。如果使用 140Ah 的电芯,则需要以 8S2P(八串两并)的方式连接。电芯之间通过焊接(通常采用激光或超声波焊接)使用大电流导体(母线)连接。

- 电池管理系统集成:电池管理系统(BMS)是关键组件,已安装到位。BMS 监控电池电压、温度和电流;平衡电池电量;并保护电池免受过充、过放和短路的影响。

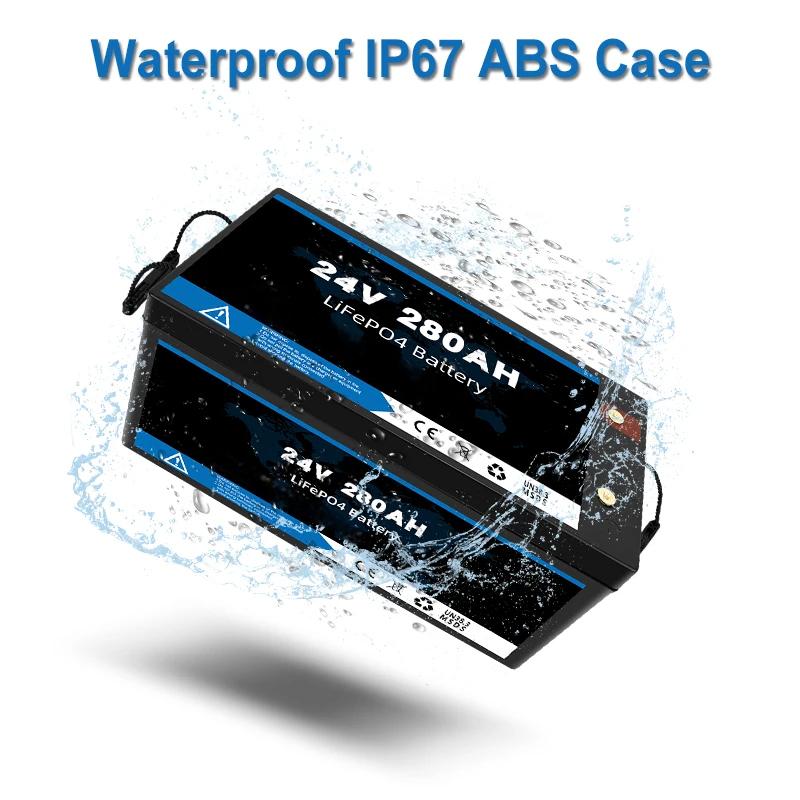

- 外壳和保护:连接的电芯和电池管理系统 (BMS) 封装在坚固的电池外壳(通常为金属或高强度塑料)中,该外壳根据应用环境而设计。如有需要,还会添加适当的散热管理组件。

- 最终测试:成品电池组在发货前会经过严格的质量控制和性能测试,包括容量测试、抗震性和安全检查。

24V 280Ah磷酸铁锂电池的发展趋势及应用

市场趋势:

24V 280Ah磷酸铁锂电池的市场需求受以下几个关键趋势驱动:

1. 能源转型:全球对可再生能源(太阳能和风能)的大力发展,需要高效的储能技术。这种电池容量非常适合住宅和商业储能系统(ESS)。

2. 电动出行:虽然大型电池组用于纯电动汽车,但 24V 系统在小型电动汽车(如低速电动汽车、叉车、高尔夫球车和物料搬运设备)中得到广泛应用,取代了铅酸电池。

3. 价格持平:制造技术的不断进步和规模经济正在稳步降低磷酸铁锂电池的价格,使其每次循环的成本与传统电池相比具有竞争力,并且通常优于传统电池。

4. 智能电池系统:集成先进的电池管理系统 (BMS) 和通信协议(例如 CAN 总线、RS485),使电池能够将其状态与外部设备通信,从而提高效率和预测性维护。

这些电池将用于哪些领域?

24V 280Ah 磷酸铁锂电池兼具适中的电压和高容量,使其成为多种高功率、深循环应用的理想选择:

- 船舶和房车电源:它可用作船舶和休闲车辆(房车)的主电源电池。其重量轻、体积小、能量密度高,可实现长时间的离网航行,并为电器、空调和其他高耗电设备提供可靠的电力。

- 离网和混合式太阳能系统:它是小型住宅或木屋太阳能储能的核心组件,可将白天产生的太阳能储存起来,供夜间或停电时使用。24V 系统通常直接与配套的太阳能充电控制器和逆变器配合使用。

- 不间断电源 (UPS):对于数据中心、医院和关键基础设施,这些电池可提供可靠的即时备用电源,是铅酸电池更轻便、更持久的替代品。

- 工业设备:它为叉车、高空作业平台 (AWP) 和地面清洁机等物料搬运车辆提供动力,快速充电和免维护运行显著减少了停机时间。

- 电信:它为蜂窝塔和远程通信设备提供备用电源,这些设备需要长寿命和最低维护成本。

总而言之,24V 280Ah磷酸铁锂电池是一款高性能能源解决方案,其特点在于安全性、长寿命和高效率。该电池的生产依赖于精准的电芯制造和精密的电池组组装工艺,而集成的电池管理系统(BMS)则是其中的关键要素。在全球可再生能源和电动汽车发展趋势的推动下,这些电池有望成为住宅、工业和特种车辆等应用领域可靠、高容量24V电源系统的标准配置。

基本参数

| 24V 280AH 磷酸铁锂电池规格 | |

| 物品 | 磷酸铁锂电池基本参数 |

| 模型 | B-24280 |

| 标称电压 | 25.6伏 |

| 额定容量 | 280安时 |

| 名义能量 | 7168瓦时 |

| 生命周期 | 4000+(80% DoD,有效降低总拥有成本) |

| 推荐充电电压 | 29.2伏 |

| 推荐充电电流 | 20.0A |

| 放电结束电压 | 20.0伏 |

| 充电温度 | -0 ~ +45 ℃ |

| 排气温度 | -20 ~ +60 ℃ |

| 储存温度 | -0 ~ +40 ℃ |

| 尺寸(长/宽/高) | 482x490x222 毫米 |

| 最小起订量 | 2 件 |

| OEM/ODM | 是的 |

| 船运 | DHL、UPS、FedEx 或海运或专线运输 |

| 应用 | 电动汽车 (EV);储能系统 (ESS);便携式电子产品;备用电源解决方案;可再生能源并网;离网电源系统;船舶和房车应用;工业和商业应用 |

评价

目前还没有评价