What’s 12.8v 50Ah LiFePO4 batteries?

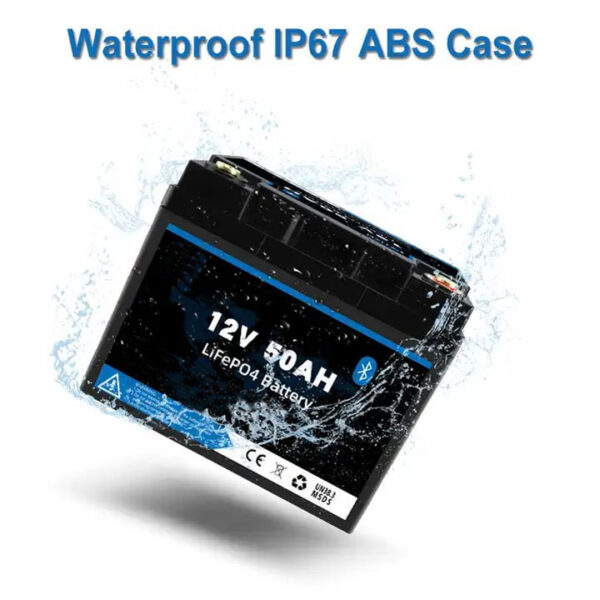

A 12.8V 50Ah LiFePO4 battery is a type of rechargeable battery that uses Lithium Iron Phosphate (LiFePO4) as its cathode material. It has a nominal voltage of 12.8 volts and a capacity of 50 amp-hours (Ah).

Here are some of the key features and benefits of 12.8V 50Ah LiFePO4 batteries:

Features:

- High energy density: LiFePO4 batteries have a higher energy density than traditional lead-acid batteries, meaning they can store more energy in a smaller space.

- Long cycle life: LiFePO4 batteries can withstand a large number of charge-discharge cycles (typically 2,000-4,000 cycles), making them much more durable than lead-acid batteries.

- Fast charging: LiFePO4 batteries can be charged much faster than lead-acid batteries, often in a matter of hours.

- Wide operating temperature range: LiFePO4 batteries can operate in a wider temperature range than lead-acid batteries, making them suitable for a variety of applications.

- Lightweight: LiFePO4 batteries are significantly lighter than lead-acid batteries of the same capacity, making them easier to handle and transport.

- Environmentally friendly: LiFePO4 batteries do not contain any toxic materials such as lead or mercury, making them more environmentally friendly than lead-acid batteries.

Benefits:

- Cost-effective: While LiFePO4 batteries may have a higher upfront cost than lead-acid batteries, their longer lifespan and lower maintenance requirements can make them more cost-effective in the long run.

- Improved performance: LiFePO4 batteries can provide better performance than lead-acid batteries in many applications, such as off-grid solar systems, RVs, and marine boats.

- Increased safety: LiFePO4 batteries are less prone to thermal runaway and other safety hazards than lead-acid batteries.

Overall, 12.8V 50Ah LiFePO4 batteries are a versatile and high-performance option for a variety of applications. Their long cycle life, fast charging, and wide operating temperature range make them an excellent choice for anyone looking for a reliable and durable battery.

What’s the Manufacturing Process of 12.8V 50Ah LiFePO4 Batteries?

The production of 12.8V 50Ah LiFePO4 batteries involves several intricate steps, ensuring quality, safety, and performance. Here’s a general overview of the process:

1. Material Preparation

- Lithium Iron Phosphate (LiFePO4): This is the cathode material. It’s synthesized by mixing lithium carbonate, iron phosphate, and a carbon source.

- Graphite: Used as the anode material. It’s processed to ensure the right particle size and purity.

- Copper Foil: Used as a current collector for the anode.

- Aluminum Foil: Used as a current collector for the cathode.

- Separator: A porous membrane that separates the anode and cathode, allowing ion flow.

2. Electrode Manufacturing

- Cathode Coating: LiFePO4 powder is mixed with a binder and conductive carbon, then coated onto the aluminum foil.

- Anode Coating: Graphite powder is mixed with binder and conductive carbon, then coated onto the copper foil.

- Drying: Both electrodes are dried in a controlled environment to remove solvents.

- Calendering: The electrodes are pressed to ensure uniform thickness and density.

3. Cell Assembly

- Stacking: The anode, cathode, and separator are stacked in a predetermined order.

- Welding: The tabs of the anode and cathode are welded to the battery case and terminals.

- Filling: Electrolyte (a lithium salt dissolved in a solvent) is injected into the cell.

- Sealing: The cell is sealed to prevent electrolyte leakage and contamination.

4. Formation

- Cycling: The battery undergoes multiple charge-discharge cycles to activate the materials and stabilize the cell’s performance.

- Testing: Various tests are conducted to ensure the battery meets specifications for voltage, capacity, internal resistance, and safety.

5. Battery Pack Assembly

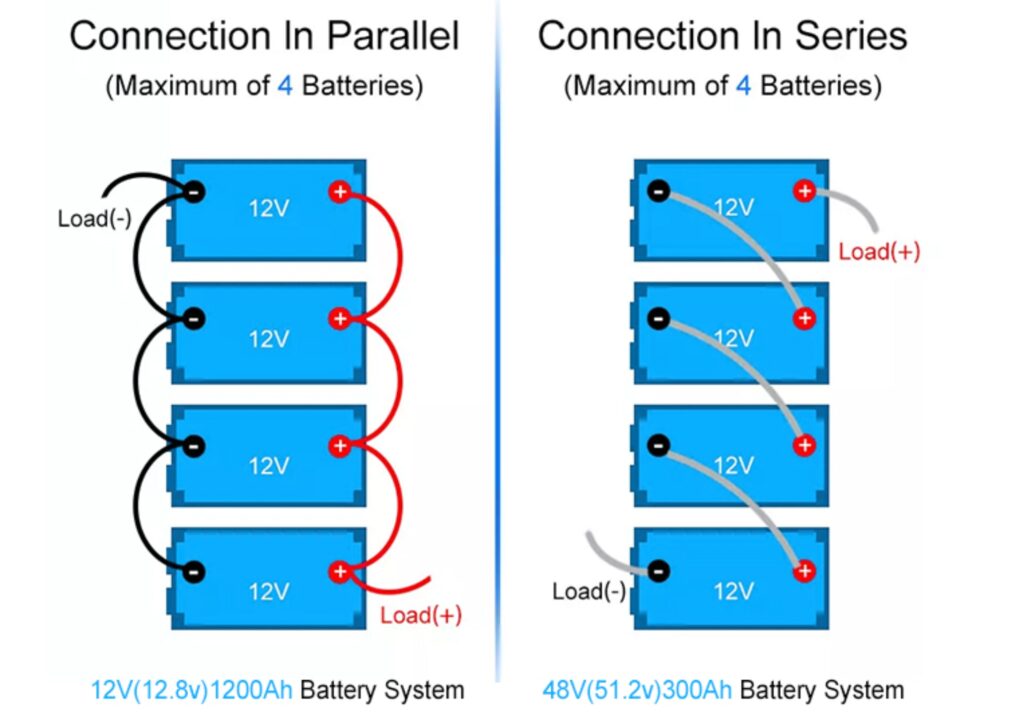

- Grouping: Multiple cells are connected in series and parallel to achieve the desired voltage and capacity.

- Wiring: The cells are interconnected using busbars or wires.

- Packaging: The battery pack is enclosed in a protective case and fitted with necessary connectors and terminals.

6. Final Testing and Quality Control

- Performance Tests: The battery pack is subjected to various tests to verify its performance, including capacity, voltage, rate capability, and cycle life.

- Safety Tests: Tests are conducted to ensure the battery pack is safe under various conditions, such as short circuit, overcharge, and over-discharge.

The manufacturing process of a 12V 50Ah LiFePO4 battery involves several steps and requires specific skills and equipment. The battery is typically assembled using a combination of individual LiFePO4 cells, a battery management system (BMS), and other components. Let’s explore the process in detail.

Firstly, the LiFePO4 cells, which are the building blocks of the battery, are manufactured separately. These cells consist of a cathode (LiFePO4), an anode (usually made of carbon), and an electrolyte. The individual cells are produced through a series of processes, including electrode preparation, cell assembly, and electrolyte filling.

Once the LiFePO4 cells are ready, they are connected in series or parallel to achieve the desired voltage and capacity. In the case of a 12V 50Ah battery, several cells with appropriate voltage and capacity ratings would be connected in series and parallel configurations in ThinkedPow

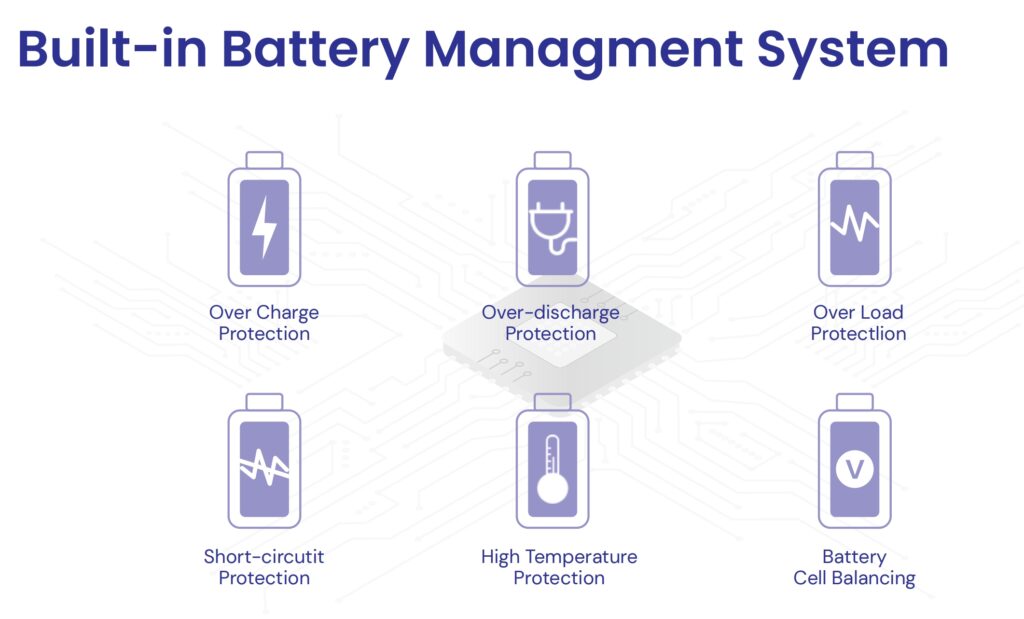

To ensure the safe and efficient operation of the battery, a battery management system (BMS) is integrated. The BMS monitors and controls various parameters such as cell voltage, temperature, and current flow. It helps prevent overcharging, over-discharging, and overheating of the battery, enhancing its lifespan and safety.

The assembly process requires skilled technicians with knowledge of battery manufacturing techniques. They should be proficient in handling LiFePO4 cells, connecting them correctly, and integrating the BMS. Additionally, the factory needs specialized equipment such as spot welders, battery testing equipment, and quality control tools to ensure the reliability and performance of the final product.

ThinkedPow’s 12V 50Ah LiFePO4 battery finds applications in various scenarios. Its high energy density, long lifespan, and safety features make it suitable for renewable energy storage systems, electric vehicles, marine applications, and off-grid power solutions.

In renewable energy storage, the battery can store excess energy generated by solar panels or wind turbines. During periods of low energy generation or high demand, the stored energy can be utilized, reducing reliance on the grid and promoting self-sufficiency.

In the electric vehicle sector, the battery provides a reliable power source with a longer driving range compared to traditional lead-acid batteries. Its safety features, such as resistance to thermal runaway, ensure the protection of the vehicle and its occupants.

For marine applications, the LiFePO4 battery offers a lightweight and compact solution with high energy density. It can power electric boats, yachts, and other watercraft, providing a clean and efficient alternative to traditional fuel-based systems.

In off-grid power solutions, the battery can be used to store energy in remote locations or areas with unreliable grid access. It enables the provision of stable power for residential or commercial purposes, such as in remote cabins, telecommunications towers, or construction sites.

Overall, the 12V 50Ah LiFePO4 battery is a versatile and reliable energy storage solution suitable for a wide range of applications. Its manufacturing process requires skilled technicians and specialized equipment to ensure the quality and performance of the final product. With its high energy density, long lifespan, and safety features, this battery is poised to contribute significantly to the advancement of renewable energy integration, electric transportation, and off-grid power solutions.

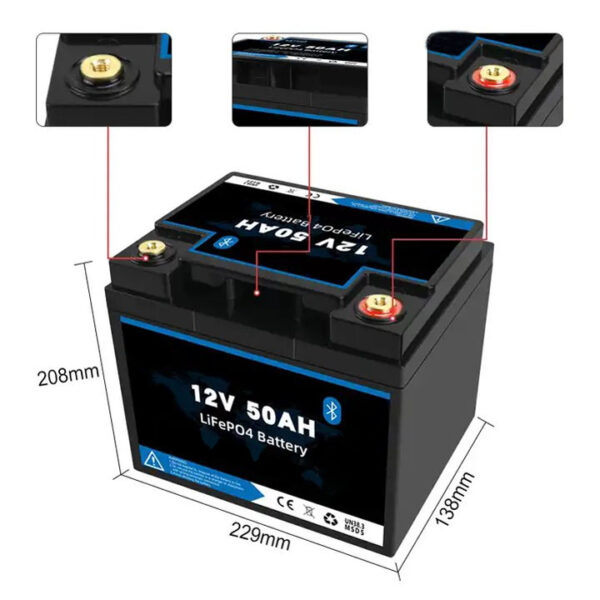

12V 50Ah LiFePO4 Battery Specification Datasheet

| Item | General Parameters |

| Rated Capacity | (Typ.) 50Ah |

| (Min.) 50Ah | |

| Nominal Voltage | 12.8V |

| Impedance | ≤100mΩ |

| End of Charge Voltage | 14.6V |

| Charge mode | CC ,CV |

| Charging time | 6 Hours/2.5 Hours |

| Over- Charge Voltage Protection (cell) | 3.65±0.05V |

| Over Discharge Cut Off Voltage | 2.35±0.05V |

| Over Current | 200A ± 30A |

| Operating Consumption Current | ≤150UA(MAX) |

| Short circuit protection | Yes, with BMS Protection |

| Operation Temperature Range | Charge :0~45℃ |

| Discharge :- 10~60℃ | |

| Storage Temperature Range | -5℃-35℃; Recommend: (25±5℃) |

| ESD Test | ±4KV |

| Working Current | Chargeing: ≤25A |

| Discharge: ≤50A |

BMS Protection System

– Over-charge protection

– Over-discharge protection

– Over-current protection

– Short circuit protection

– Temperature detection protection

– Balance function

– Bluetooth function

Reviews

There are no reviews yet.